Sample Results with the Developed Code for Transient Turbocharged Diesel Engine Operation

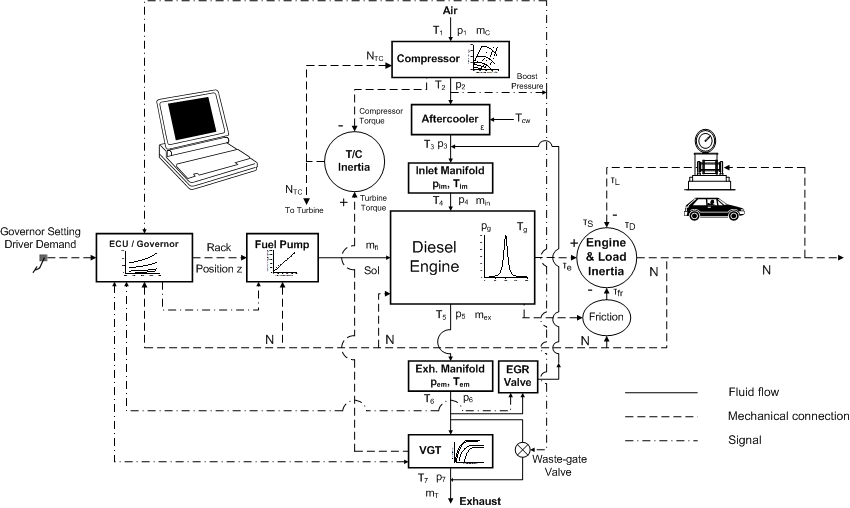

Block diagram of developed transient simulation code

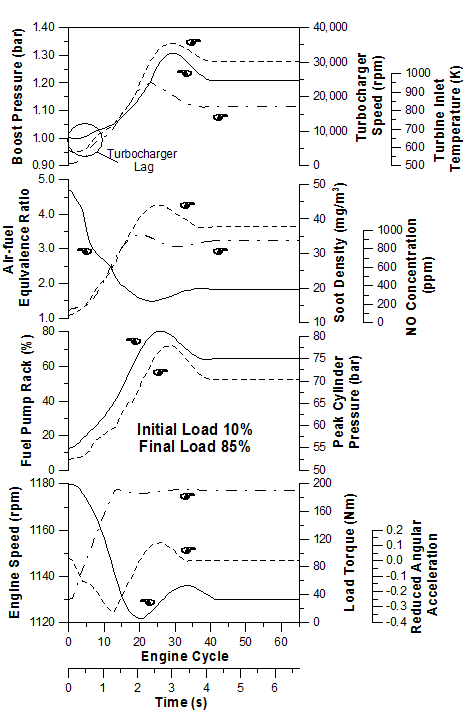

6 cylinder, 16.62 L, turbocharged diesel engine response to an increase in load

(C.D. Rakopoulos, E.G. Giakoumis, “Diesel engine transient operation”, Springer, London, 2009)

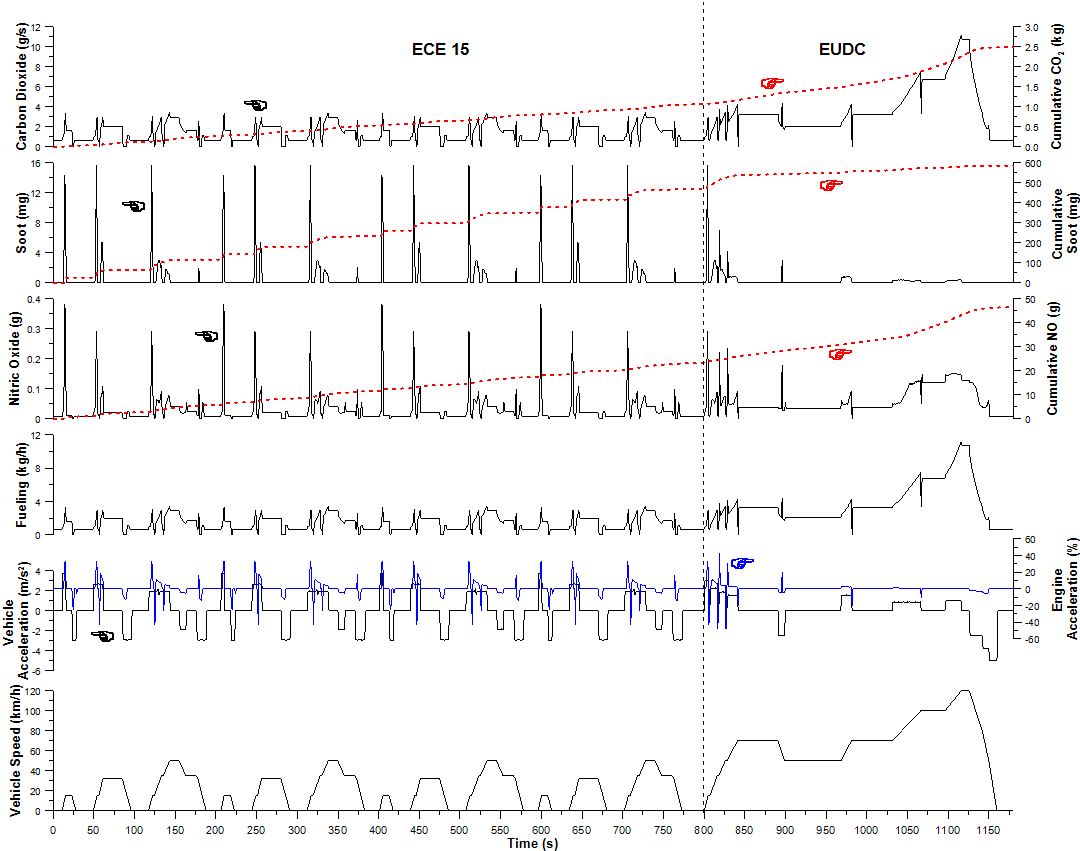

Calculated fueling and soot, NO and CO2 emissions during the NEDC of a turbocharged diesel-engined vehicle

(E.G. Giakoumis and S.C. Lioutas, “Diesel engined vehicle nitric oxide and soot emissions during the European light-duty driving cycle

using a transient mapping approach”, Transportation Res. Pt. D, Vol. 15, pp. 134-143, 2010)

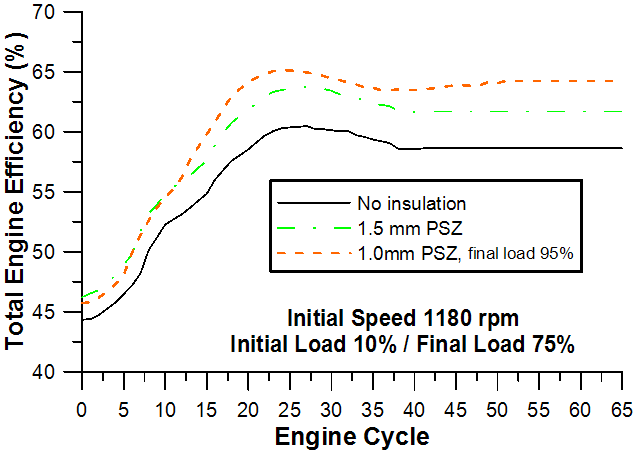

Response of insulated engine 2nd-law efficiency (=work + exhaust gas to ambient) to an increase in load

(C.D. Rakopoulos and E.G. Giakoumis, “Study of the transient operation of low heat rejection turbocharged diesel engine

including wall temperature oscillations”, SAE Paper No. 2007-01-1091)

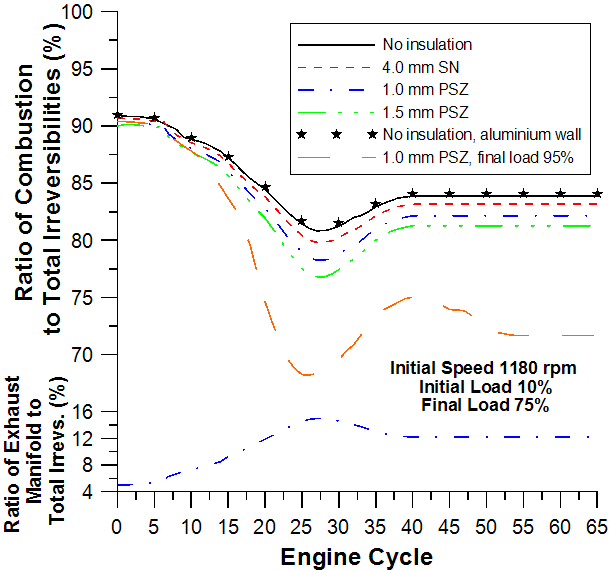

Response of percentage combustion irreversibilities to an increase in load

(E.G. Giakoumis, “Cylinder wall insulation effects on the first- and second-law balances of a turbocharged diesel engine

operating under transient load conditions”, Energy Conversion and Management, Vol. 48, pp. 2925-2933, 2007)

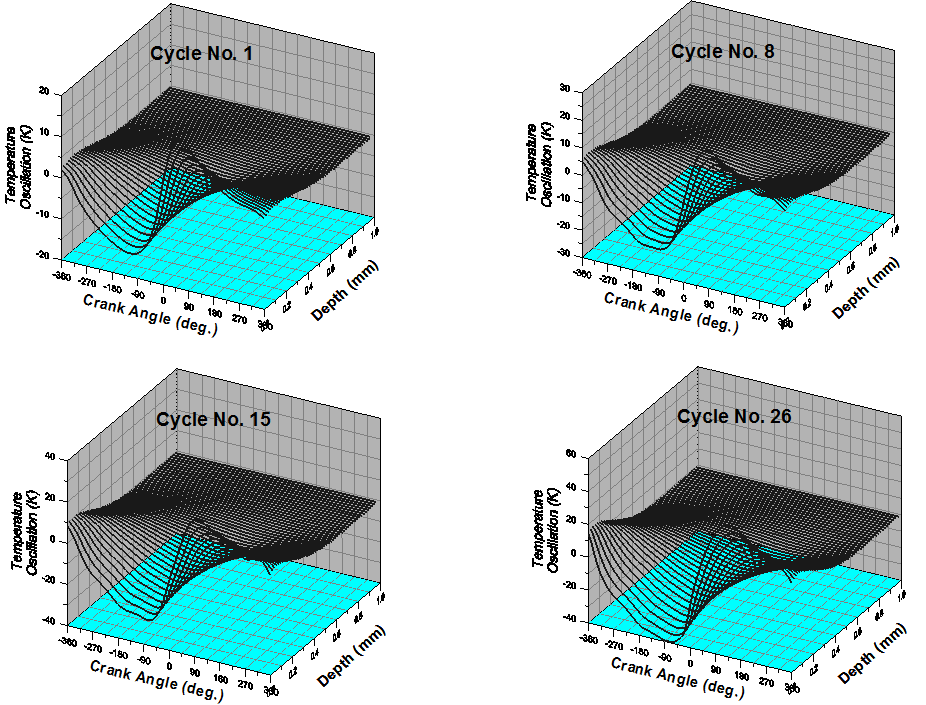

Variation of wall temperature with depth x (inside the wall) and crank angle φ, for 1.0 mm PSZ coating,

during four discrete cycles of a turbocharged diesel engine transient load increase

(C.D. Rakopoulos, E.G. Giakoumis and D.C. Rakopoulos, “Study of the short-term cylinder wall temperature oscillations during

transient operation of a turbocharged diesel engine for various insulation schemes”,

Int. Journal of Engine Research, Vol. 9, No. 3, pp. 177-193, 2008)

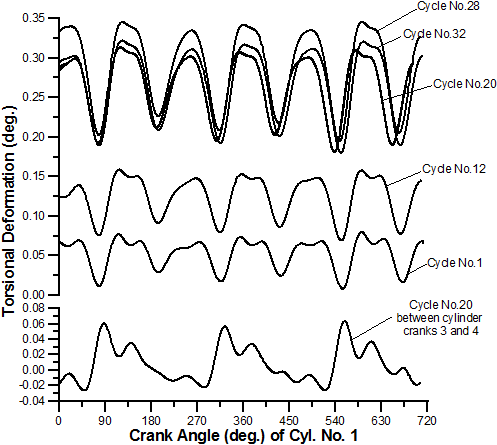

Development of torsional deformation between engine flywheel and load (upper sub-diagram)

and between cylinder cranks 3 and 4 (lower sub-diagram) during various cycles

of a six-cylinder engine load increase transient event

(E.G. Giakoumis, I.A. Dodoulas and C.D. Rakopoulos, “Instantaneous crankshaft torsional deformation

during turbocharged diesel engine operation”, International Journal of Vehicle Design, Vol. 54, pp. 217-237, 2010)

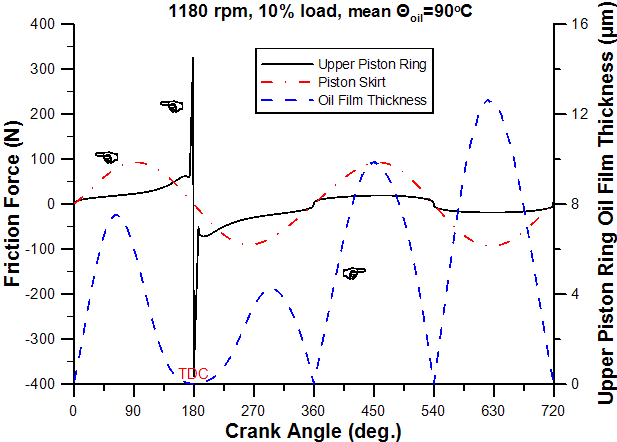

Variation of upper piston ring friction force and oil film thickness during an engine cycle

(C.D. Rakopoulos, E.G. Giakoumis and A.M. Dimaratos, “Evaluation of various dynamic issues

during transient operation of turbocharged diesel engine with special reference to friction development”,

SAE Paper No. 2007-01-0136)

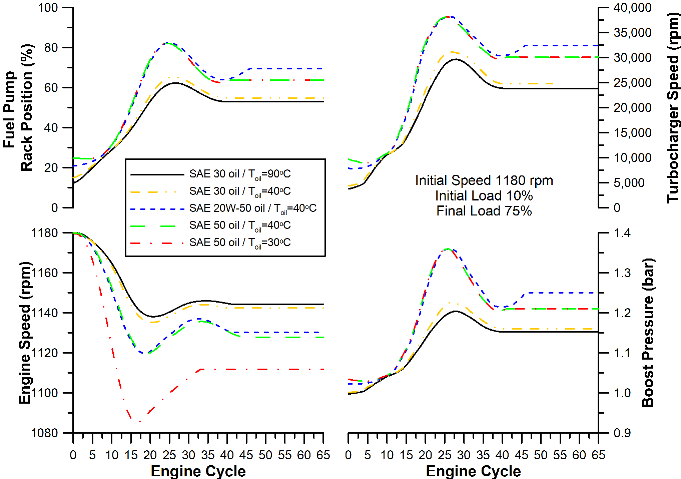

Engine and turbocharger properties response during a 10–75% load increase transient event

for various oil-types and temperatures

(E.G. Giakoumis, “Lubricating oil effects on the transient performance of a turbocharged diesel engine”,

Energy, Vol. 35, pp. 864-873, 2010)

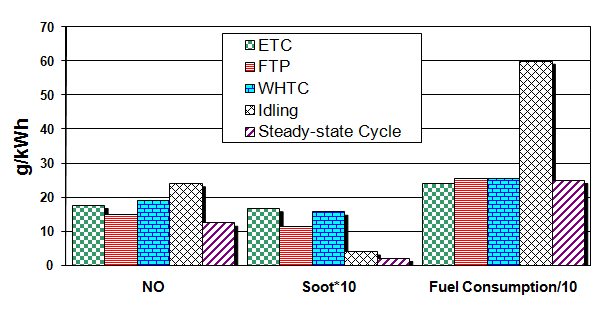

Calculated comparative emissions and fueling between three heavy-duty transient cycles

(European ETC, American FTP and world-wide WHTC) and two fictitious ones

(a continuous 'steady-state' at the mean engine speed and loading of the ETC, and an 'idling' one)

for a turbocharged diesel engine

(E.G. Giakoumis and A.I. Alafouzos, “Comparative study of turbocharged diesel engine emissions

during three different Transient Cycles”, Int. J. of Energy Research, Vol. 34, pp. 1002-1015, 2010)

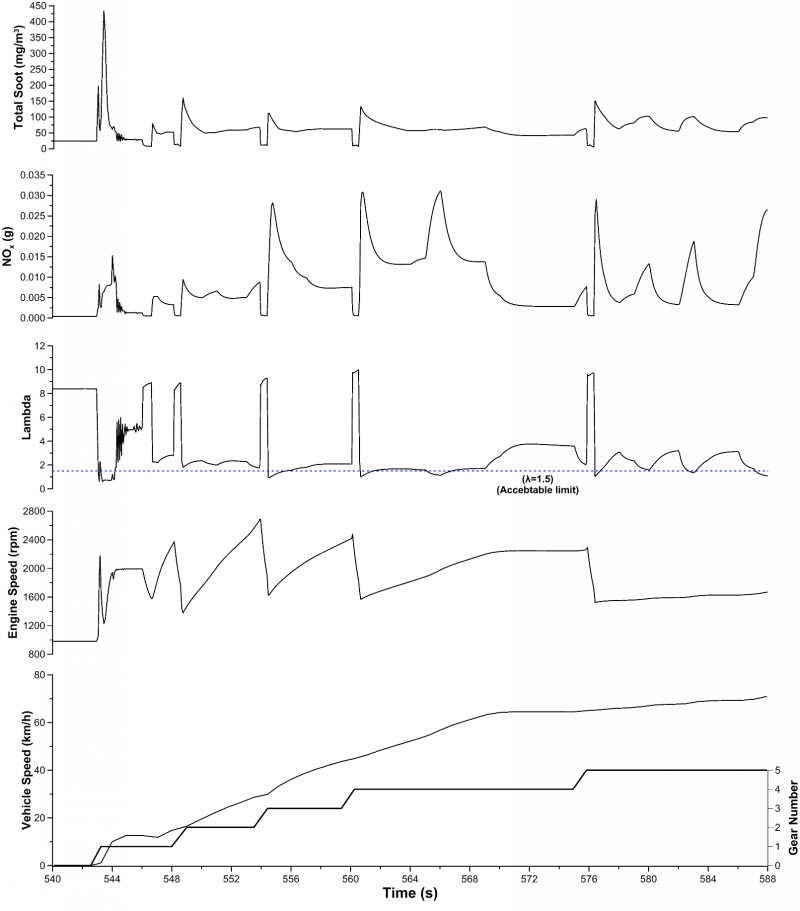

Development of NOx and soot during a portion of the UDDS driving cycle for a turbocharged diesel-engined truck

(simulation with the use of the GT-Power software)

(E.G. Giakoumis and A. Alysandratou, “Performance and emissions of a heavy-duty truck during the UDDS driving cycle: Simulation analysis”, ASCE, J. of Energy Engineering, Article No. E4015011, 2016) |