Research

Group highlights

Even though Masonry is one of the oldest building materials, our understanding of its behavior at the level of the structure (system level) is limited. Therefore, there is a need for extended shake table testing. But full scale shake table testing is epxensive. Funded by our ERC StG we have developed a methodology to additively manufacture 1:15 physical models of masonry. We tested mulitple identical models on a shake table within a cetrifuge to preserve similitude of stresses, each one with a different ground motion. Contrary to the response of a single specimen, the statistics of the responses to multiple ground motions was found predictable.

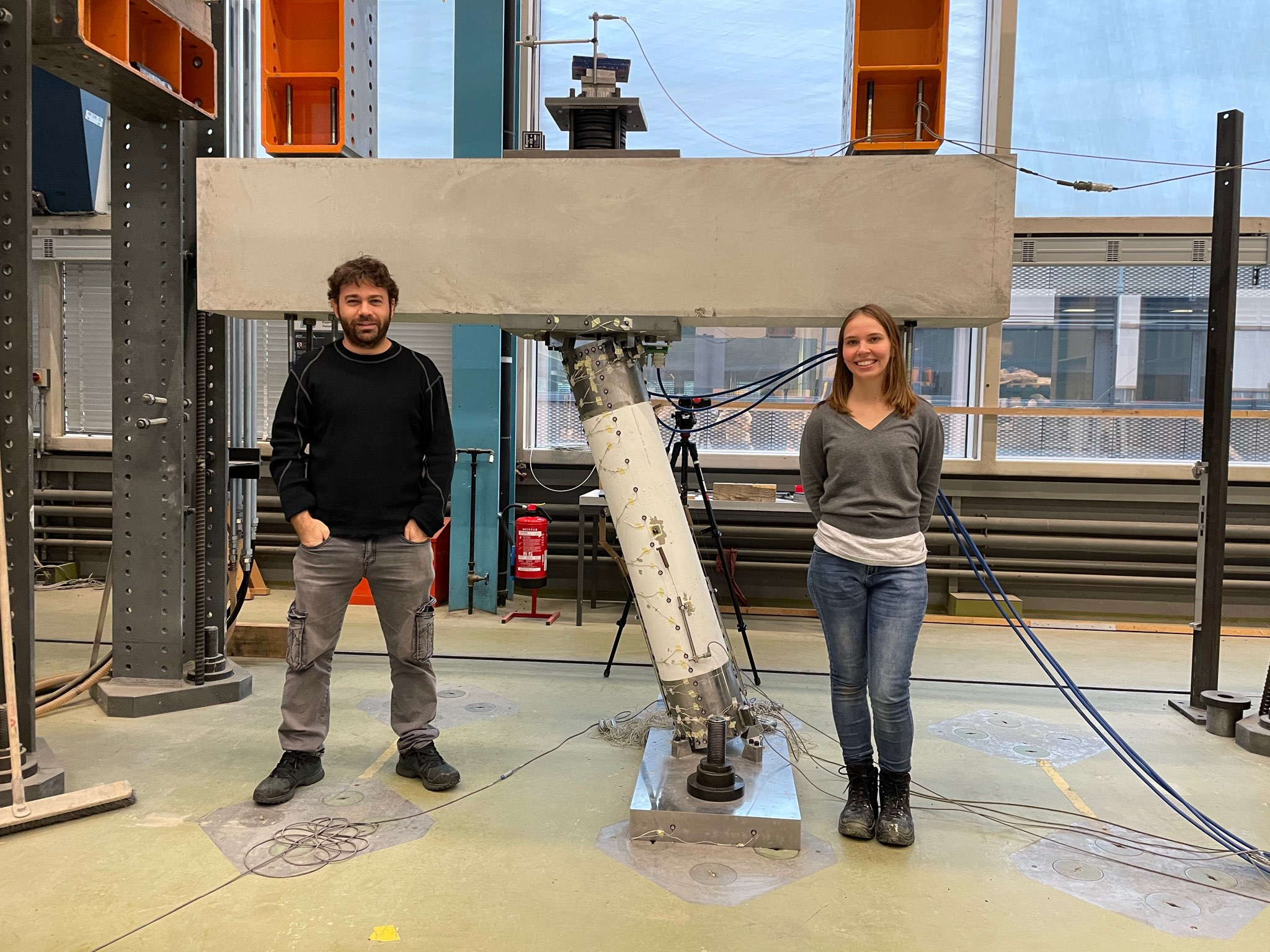

For more than 15 years we have been working on the response of rocking structures, including conceptual models, advanced numerical modelling, small- and large-scale testing. Research related to rocking finds applications in the seismic behavior of ancient temples and unanchored equipment, while it can be used as a seismic design strategy for precast RC bridges.

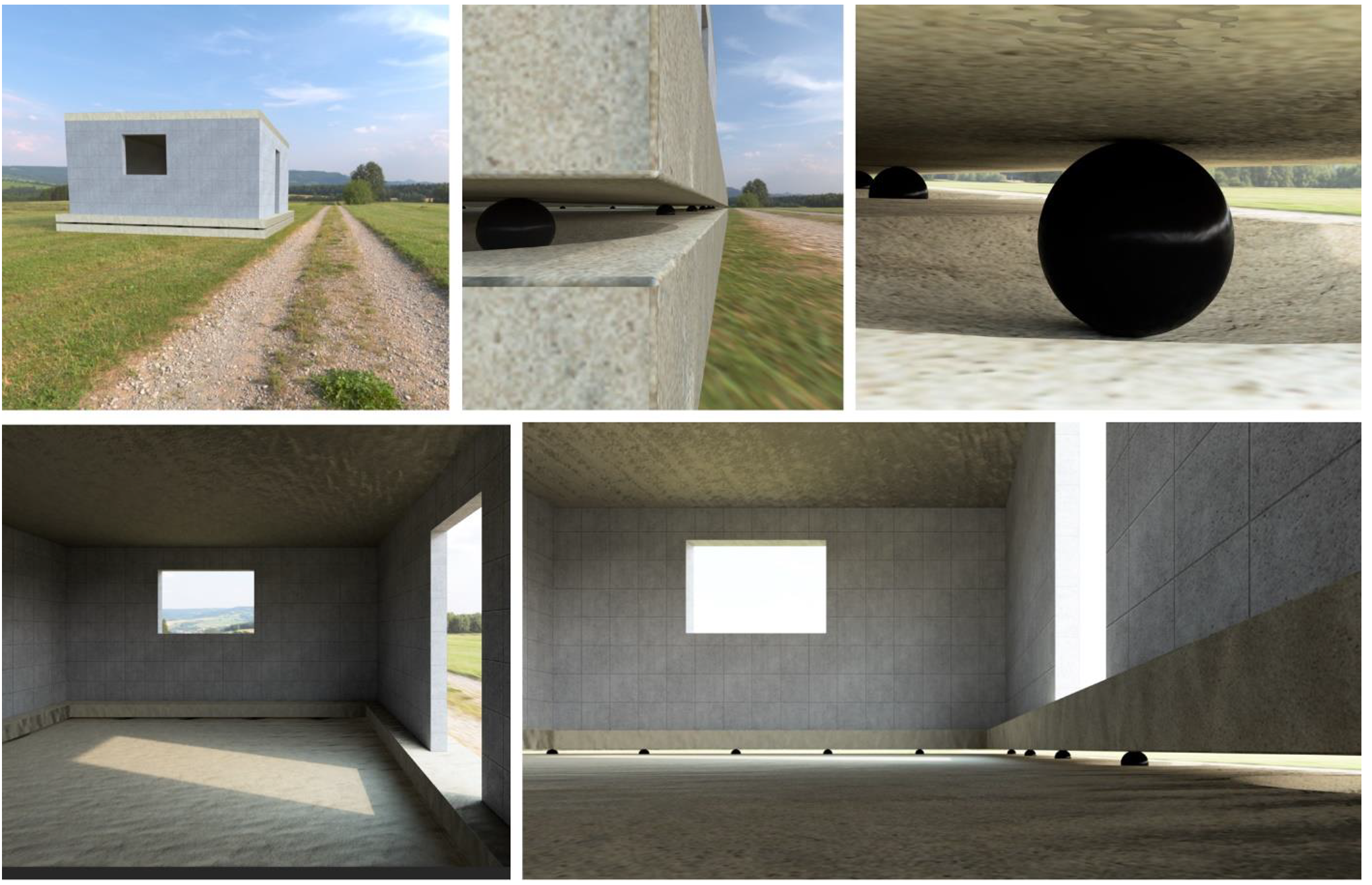

Out of our work on seismic isolation, we distinguish our recent project on low cost seismic isolation. Because seismic isolation has been mainly applied in high-importance projects, usually in rich countries, we try to reduce its cost, so that it can be applied in more projects, even in low-income countries. To this end, together with colleagues from the Latin America we have studied a system based on an elastomeric ball rolling on a spherical concrete surface. We also studied a very low cost method based on tennis balls filled with cement grout.

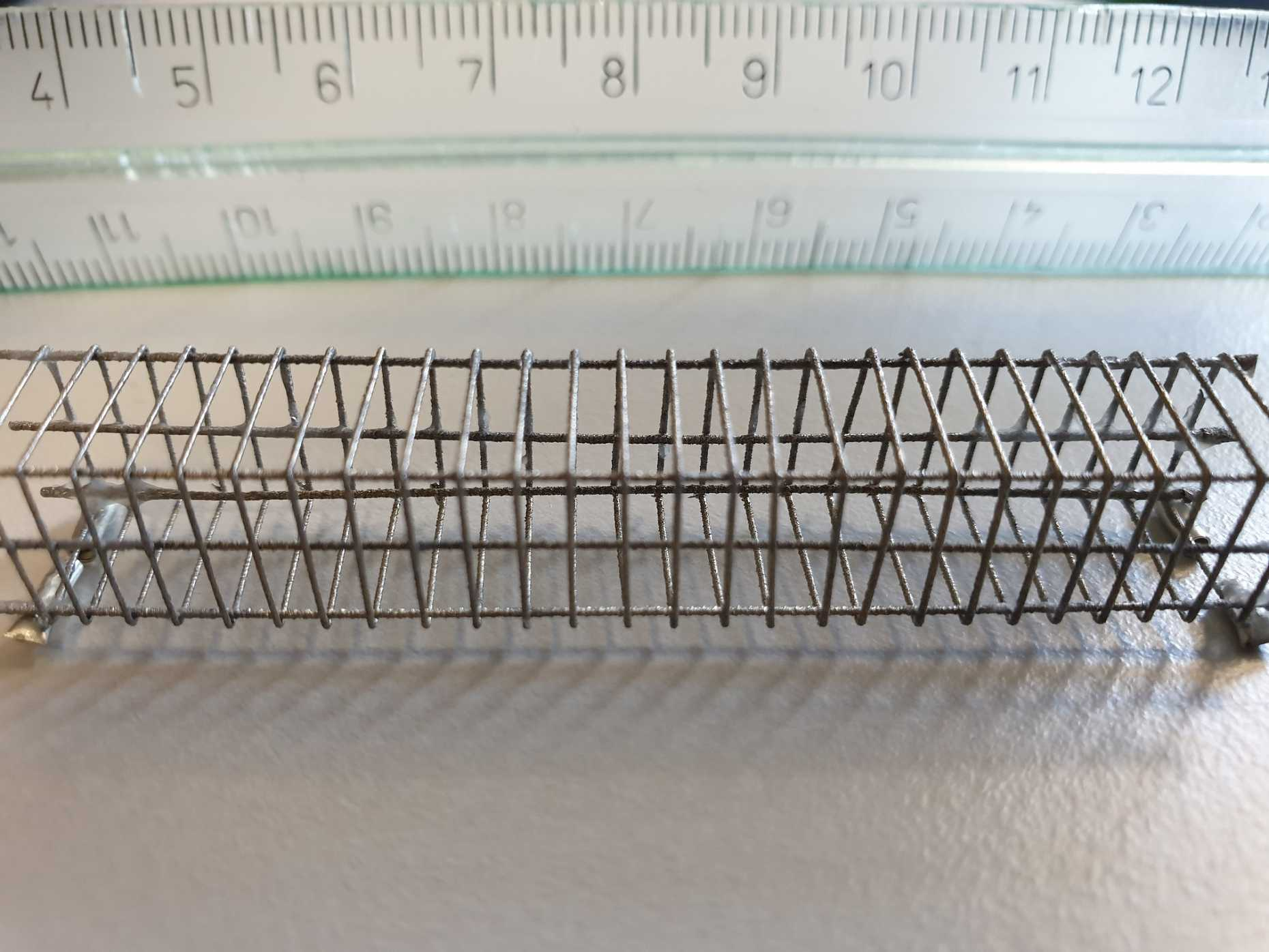

Small scale models of RC can be tested on a shake table within a centrifuge to preserve similitude. This would reduce the testing cost and would also allow for experimentally studying problems that are impossible to study at full scale. But the required scales (as low as 1:40 to 1:30) give rise to a number of manufacturing and similitude questions. We have used metal additive manufacturing to build whole reinforcing cages with behavior close to real reinforcement and gypsum-based mortar to create model concrete that behaves close to real concrete. The bond behavior between the model concrete and reinforcement, as well as the cyclic behavior of small scale columns and joints closely resemble the behavior of their full scale counterparts.

Modern civil engineering relies heavily on Steel and Reinforced Concrete (RC), but many developing regions lack these materials while having access to sustainable, low-cost alternatives like bamboo. Historically overlooked, bamboo has been used for centuries in Asia, Africa, and Latin America, showing remarkable resilience in earthquakes. Its main challenge lies in variability and lack of standardization, since species and even specimens differ greatly in properties. In this project we screened diverse bamboo strains and performed a Genome-Wide Association Study (GWAS) to link strength with genetics. The findings could enable standardized, genetically improved bamboo, transforming construction in rapidly growing regions.